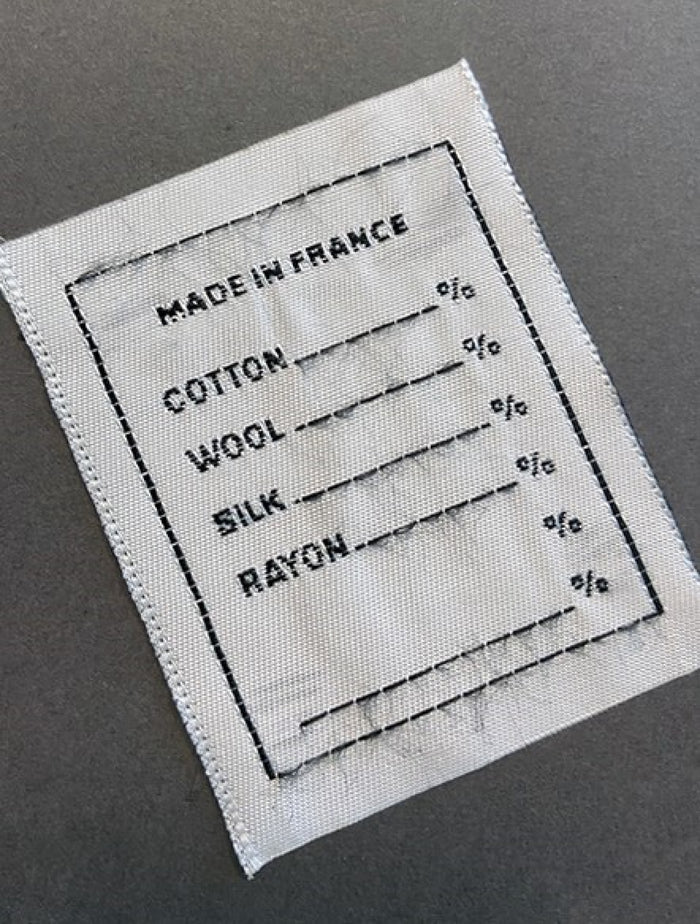

At CO&IN, we understand that quality and customization are key, especially when it comes to representing a brand's unique character.

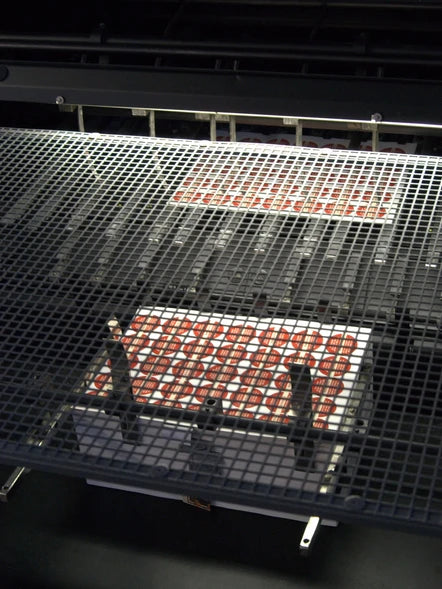

Precisely for this reason, we are proud of our ability to offer a wide range of customizations, even for productions with limited quantities.

This flexibility is a great competitive advantage that allows us to meet the specific needs of major brands in the fashion, food, beauty and design sectors.

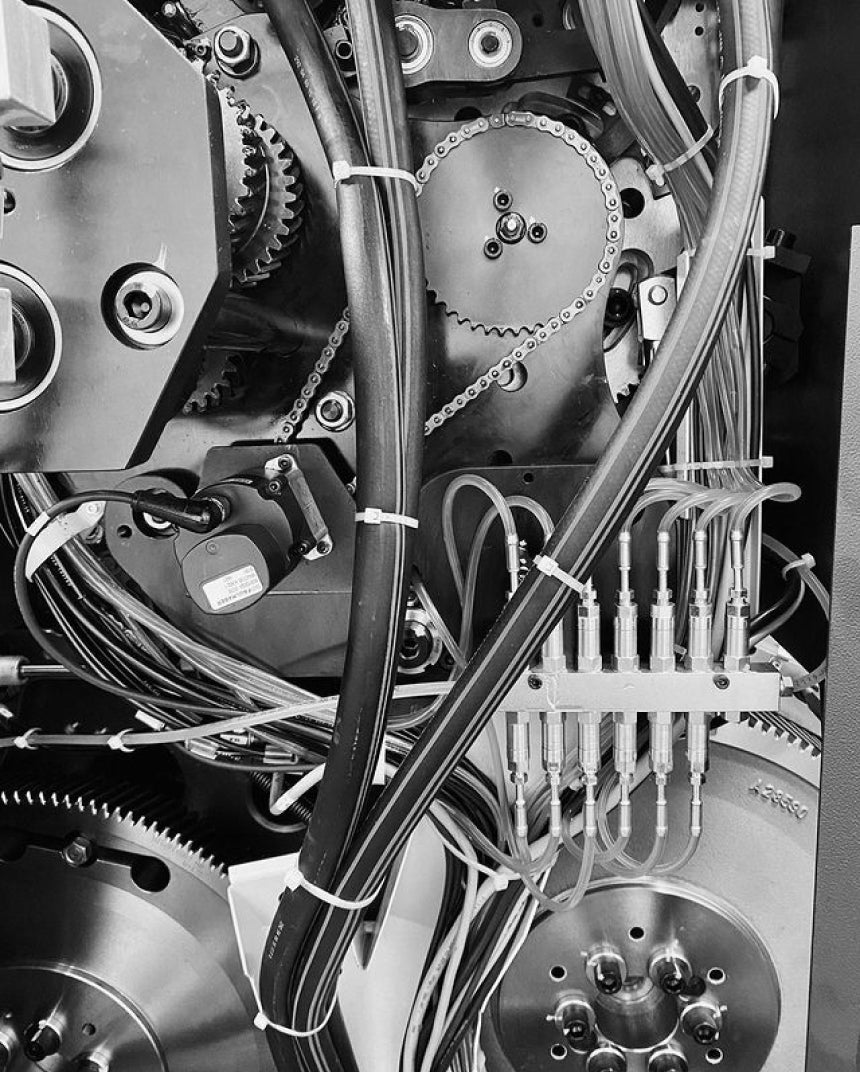

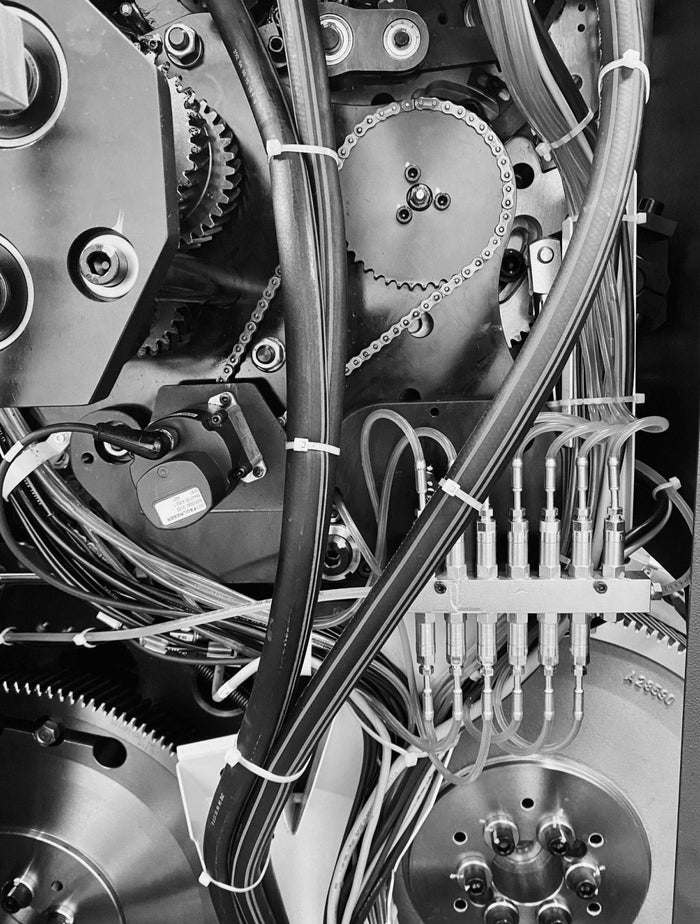

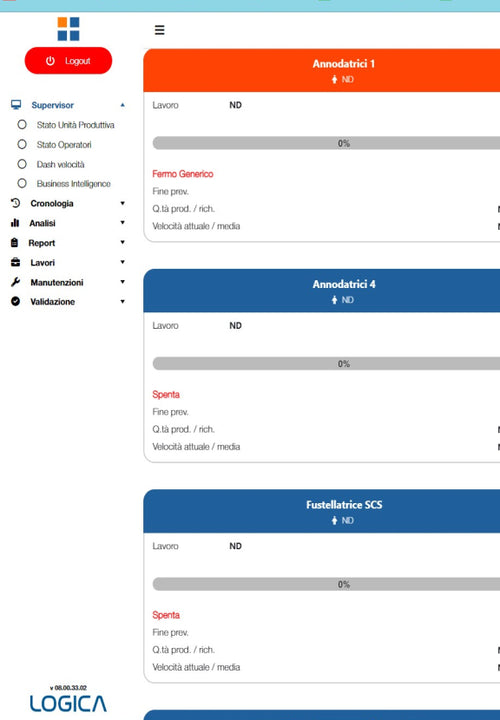

Our versatility in production allows us to be particularly agile and reactive, successfully tackling the challenges that the most exclusive and customized projects present.

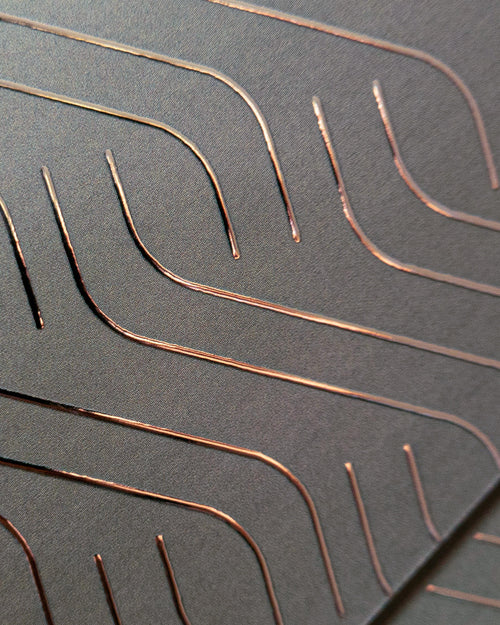

Whether it is a small edition of luxury packaging for a special event or a limited series for a product launch, CO&IN works closely with you to ensure that every aspect of the packaging is perfectly aligned with the vision and standards of the brands.

Our attention to detail and commitment to exceeding customer expectations make it possible to transform even the most ambitious ideas into tangible realities, giving your brand that touch of uniqueness that sets it apart in the market.